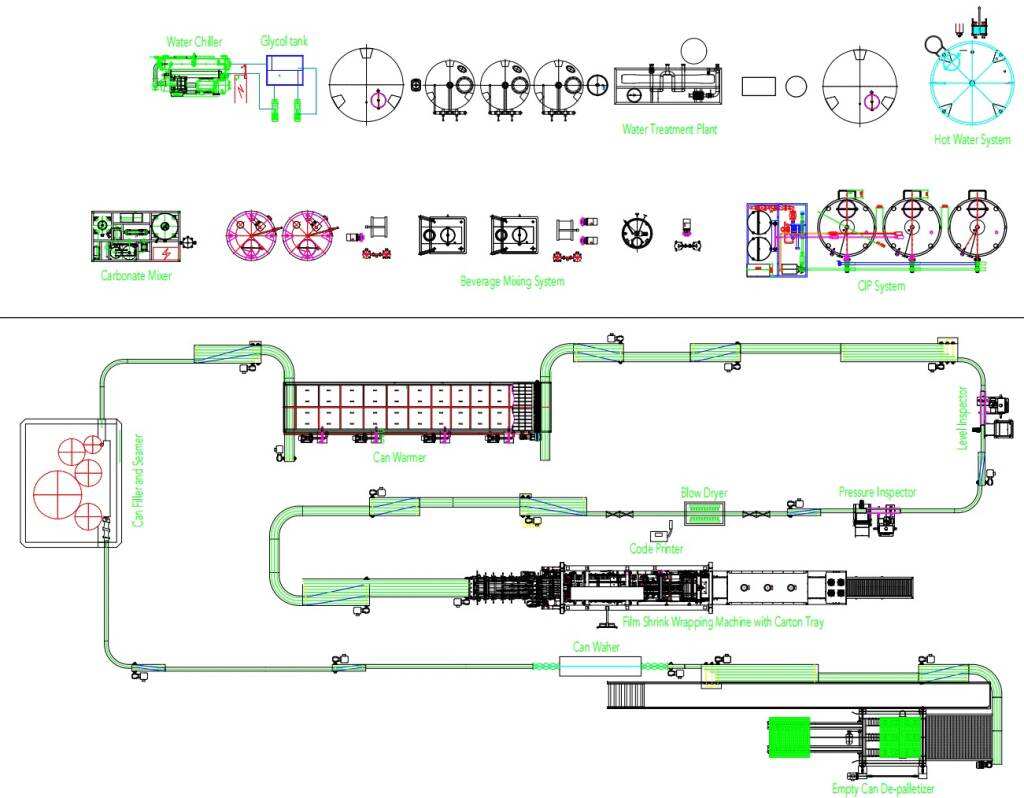

we provide the complete pop cans / tin can filling and package solution, from can depalletizer, can rinsing machine, can filling & sealing monoblock machine, leakage check, liquid nitrogen dosing machine, pasteurizer tunnel, blow dryer, carton package, film package system, which is widely used for the beverage, beer, juice, sauce industry and so on.

|

Model |

GD12-1 |

GD18-6 |

GD24-6 |

GD32-8 |

GD40-8 |

|

Capacity (500ml/can/h) |

2000-3000 |

5000-6000 |

7000-8000 |

9000-10000 |

11000-13000 |

|

Can Size |

150ml to 500ml (Special size can be customized) |

|

|||

|

Filling Temperature |

0-4℃ |

0-4℃ |

0-4℃ |

0-4℃ |

0-4℃ |

|

Rated Power |

5.5KW |

6.5KW |

7.8KW |

8.5KW |

9.2KW |

|

Overall Size |

2800*1600*2000mm |

3000*1700*2000mm |

3200*1800*2000mm |

3500*1950*2000mm |

3800*2150*2000mm |

|

Wight |

3000kgs |

4000kgs |

4800kgs |

5200kgs |

6200kgs |

The machine is suitable for filling and sealing beverage or brewage industry, it have such features as rapid filling and sealing speed, consistent height from the liquid level in the can to the can mouth after filling, stable machine operation, good sealing quality, beautiful and decent appearance, convenient use and maintenance, touch screen operation, frequency conversion speed adjustment, etc. It is the most ideal filling and sealing device for beverage plants and brew houses.

It can replace the manual can arrangement, increase production efficiency, it is an indispensable ideal device for middle and large sized beverage plants, plc programmable computer automatic controller, photo-electricity switch, over travel-limit switch and pneumatic control,etc, use the famous brand from germany and japan and taiwan.

Including Liquid level check, vacuum leakage test, liquid nitrogen dosing machine.

With various zones treatment of circulated cooling water and the treatment time can be adjusted according to the user’s requirement. The machine are specially designed for the pasteurizer tunnel, can be used for the carbonated drink, juice, beer, food product.

As customer request and market demand, we provide the better solution for the final product package.

We have various kinds of options. Labeling machine have the PVC sleeve label, BOPP hot glue label, adhesive stick label, wet glue label, and packing machine have the film shrink machine and carton box package.

We design the factory layout based on customer factory sizes, whole line design is based on famous brand motors and automatic lubricant system, and with less power consumption, and save space.