Why Choose Us

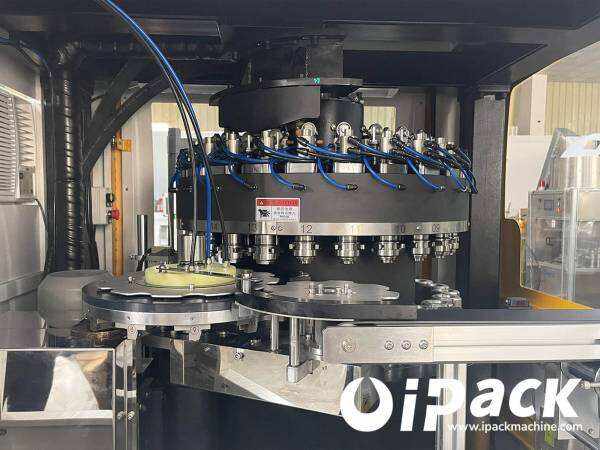

Zhangjiagang Ipack Machine Co., Ltd was established in 2009, it covers an area of 15,000 square meters, is one of the leading enterprises specializing in research and production of liquid and beverage packing machines. Our main products are: beverage treatment plant, filling machine for beverage and daily chemical articles, labeling machine, film package and carton packing machine. beverage water treatment and production assembly. We are not only a machine making enterprise, but we can also supply all class of turnkey project request of customers, it is to say, workshop designing, machine layout designing, water, gas and electric cable layout designing, label and bottle designing, etc. Our mission is to let customers’ plant run well and help customers win market.